Evolution of Bently Nevada 3500 System: A Paradigm in Machinery Protection

AutoControl GlobalAutoControl Global July 18, 2024Introduction

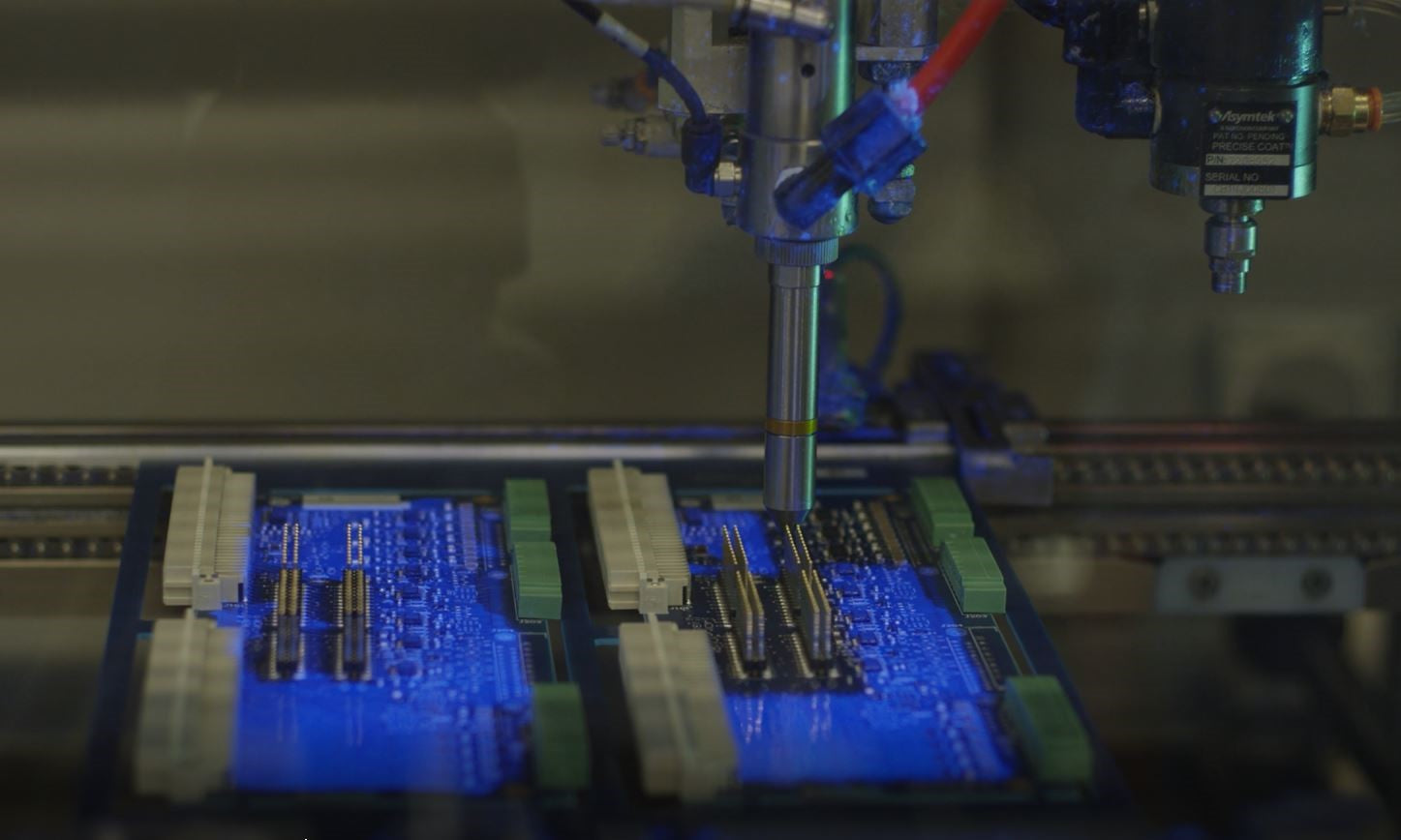

The Bently Nevada 3500 system stands as a pinnacle in machinery protection and condition monitoring, embodying over 60 years of domain expertise and continuous innovation. Developed into a flexible and scalable rack-based platform, it serves as a cornerstone for safeguarding critical machinery in industrial settings.

Decades of Development

For over 20 years, relentless product development has honed the Bently Nevada 3500 system into a finely tuned mechanism. This evolution underscores its role in reliably protecting machinery while accommodating the dynamic needs of industrial operations.

Scalability and Flexibility

One of the system's key strengths lies in its scalability. It adapts seamlessly to varying operational scales and complexities, ensuring comprehensive protection across diverse industrial environments. Furthermore, its modular design facilitates flexible configuration tailored to specific machinery requirements.

Integration with System 1 Software

Integral to its functionality is the integration with Bently Nevada’s System 1 software. This advanced platform enhances diagnostic capabilities, enabling precise and detailed machinery analysis critical for effective condition-based maintenance strategies.

Enhanced Diagnostic Capabilities

System 1 software empowers engineers with advanced diagnostic tools. These tools leverage comprehensive data analytics to provide deep insights into machinery health, facilitating proactive maintenance interventions before issues escalate.

Reliability and Operational Continuity

The system’s robust architecture ensures continuous operation under demanding conditions. Its reliability is a testament to meticulous engineering and rigorous testing, aimed at minimizing downtime and optimizing operational efficiency.

Industry Best Practices

Embodying best practices in machinery protection, the Bently Nevada 3500 system sets industry standards. Its methodology integrates decades of field experience and customer feedback, ensuring alignment with evolving industrial requirements.

Future Prospects

Looking ahead, the system remains poised to evolve further, incorporating emerging technologies and methodologies. This forward-looking approach underscores its commitment to staying at the forefront of industrial machinery protection and condition monitoring.

Conclusion

In conclusion, the Bently Nevada 3500 system represents more than just a technological solution; it epitomizes a legacy of reliability, innovation, and commitment to enhancing industrial operational excellence. With its robust framework and advanced diagnostic capabilities, it continues to empower industries worldwide in safeguarding their critical assets and optimizing performance.