Robots & Sustainable Homes: ABB, AUAR Project

AutoControl GlobalAutoControl Global February 28, 2025Robotic Precision: The Pulse of Innovation

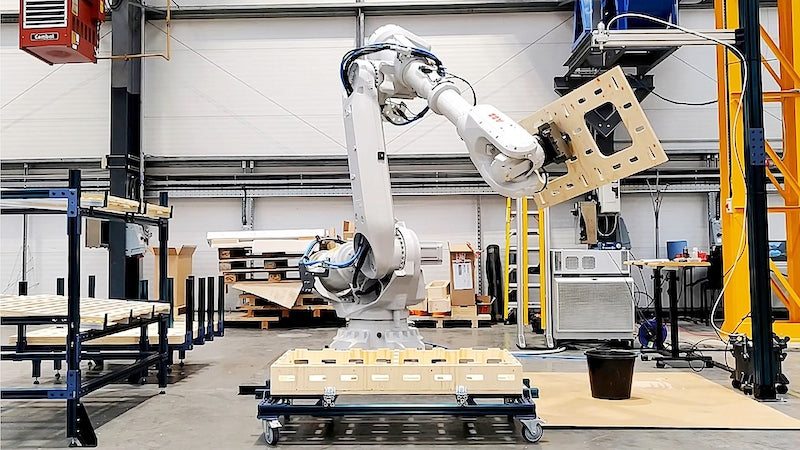

AUAR's innovative micro-factories technology lies at the core of this initiative. Additionally, these micro-factories, powered by ABB's state-of-the-art robots, will build the building with unrivaled accuracy. Therefore, this building process, which is automated, not only enhances efficiency but also minimizes waste, a secret to reducing the industry's carbon footprint. "The steel building sector, which itself generates 40% of global CO2 emissions, is going to some lengths to build more sustainably and responsibly," said Craig McDonnell, ABB Robotics vice president Business Line Industries. "To enable this transition, robotic automation can play an important part, by reducing waste and assisting in addressing the environmental and manpower challenges confronting construction companies today."

A Living Laboratory for Climate-Neutral Solutions

Furthermore, "ConstrucThor" will be a living laboratory at the OpenThor Living Lab in Thor Park, Genk, Belgium. In addition, this project, in partnership with KU Leuven University, will study energy-neutral infrastructure and climate-neutral building materials. "We are thrilled and honored that our technology is being used to build this cutting-edge facility, a testament to AUAR and ABB's shared enthusiasm for innovation and green building practice," said Mollie Claypool, co-founder and CEO of AUAR. "Our computer-controlled modular construction micro-factories squarely address the problems of the industry–reducing cost, schedule and carbon footprint of building homes–and this project will prove that our revolutionary building approach will be instrumental in developing future sustainable societies."

Circularity and Innovation: Building a Greener Future

"The AUAR-ABB Robotics partnership presents an engaging vision for building and construction in the future. We pushed this vision to the next level in the ConstrucThor project by investigating the application of recycled wood in modular walls. This approach not only aligns robotics and modular construction but also revolves around circularity," ConstrucThor Project Coordinator Tim Verhetsel at KU Leuven discussed. Also, using recycled wood helps to reinforce the project's focus on circular economy.

The Future of Automated Construction

Additionally, AUAR and ABB Robotics have been working on automating building methods using robotic mobile micro-factories. The micro-factories produce cost-effective, high-quality timber frame wall, floor, and roof panels at low prices. Also, vision-driven and AI-based advanced robots simplify the building process, enhancing speed, flexibility, and uniformity. "For example, a robotic micro-factory is able to manufacture the core and shell of a single house within less than 12 hours, which can subsequently be rapidly assembled on-site." It is amazing to learn how quickly and effectively houses can now be manufactured.

Expanding the Vision: A Global Network of Micro-Factories

Finally, AUAR and ABB are constructing a global network of local micro-factories which enable homes to be manufactured close to their final destinations. AUAR has already established micro-factories in the UK, Belgium, and the US, with further development in the pipeline. Next year, they will have 10 micro-factories in North America and Europe.