Siemens' MACHINUM and SINUMERIK 828D at IMTEX 2025

AutoControl GlobalAutoControl Global February 02, 2025Siemens' Big Moves at IMTEX 2025

At the recently held IMTEX 2025, Siemens made some big announcements. First, they unveiled MACHINUM—a digitalization portfolio. This is not just any other offering but a set of well-crafted solutions for the Indian machine tool industry. You see, the Indian market has been growing rapidly, especially with increased investment from high-end manufacturing units for both local consumption and export. A huge demand is seen to exist for machine tools that can offer high precision, customization, and seamless integration into manufacturing processes. Siemens is thus taking a forward step by recognizing this need and stepping in with MACHINUM.

MACHINUM: A Digital Solution for the Machine Tool Industry

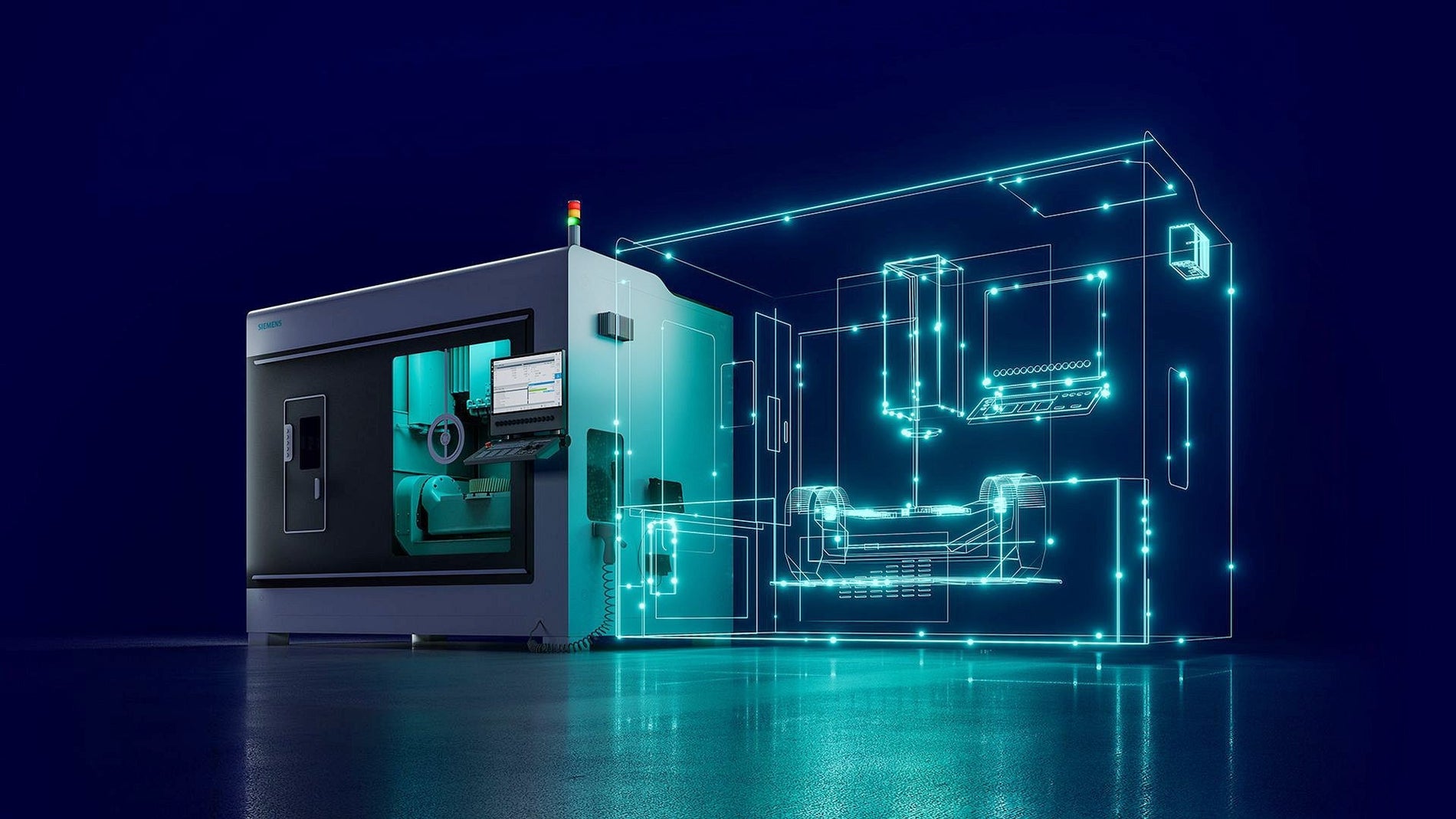

MACHINUM is truly a game changer: to potentially reduce setup time by up to 20%, and to cut down both cycle times and energy consumption by as much as 18% is just great! It forms an integral part of Siemens Xcelerator, which is an open digital business platform. It's an integrated software and IoT-enabled hardware platform with a varied ecosystem of partners and a marketplace. In the machine tool industry, companies can have an easier, faster, and scalable digital transformation through MACHINUM. Like equipping them with a powerful toolbox, it upgrades manufacturing and design processes.

The Upgraded SINUMERIK 828D: A Step Forward in Technology

Apart from MACHINUM, Siemens will introduce the enhanced 5th generation SINUMERIK 828D. That's not a minor thing. What the enhancement does is open up the possibilities to SINUMERIK Run MyVirtual Machine, which is revolutionary in itself. That allows the user to create, validate, and optimize NC programs virtually with the digital twin of the machine but without disturbing production. Think of that. This will reduce the setup time on the real machine by up to 20% and minimize production risks. Besides, it is featured with cutting features like Digital Twin readiness, effortless HMI customization, and 40% faster program buffering. All these aspects put together ensure that the overall operations are smoothed out and efficiency increased like never before.

Energy Efficiency and Sustainability: Siemens' Commitment

Vijay Pratap Singh, head of motion control, digital industries at Siemens Ltd, highlighted the need for energy efficiency. Siemens energy-efficient hardware, operational technology, and digitalization are the keys toward ensuring higher sustainability in machine tool manufacturing. At IMTEX 2025, Siemens is not only showing off its components with high energy efficiency and a lower carbon footprint but also applications that can compensate, recover, and limit energy consumption. This is a win-win situation. The economy in cost-saving by machine tool manufacturers and users can do more with less.